Electrode Φ6×6mm

Ⅰ . Manufacturing and inspection standards of products

1、GB/T1408.1-2006《Electrical strength of insulating materials -Test methods - Part 1:Tests at power frequencies》

2、GB/T1408.2-2016 《 Insulating materials -Test methods for electric strength -Part 2:Additional requirements for tests using direct voltage》

3、JJG 795-2016 《Withstanding Voltage Testers》

Ⅱ . Applicable test method standards

1、GB/T1695-2005《 Rubber, vulcanized - Determination of electrical breakdown strength and voltage resistant at commercial power frequency》

2、GB/T3333-1999《Cable paper—Determination of electrical strength at power frequence》

3、GB/T12913-2008《Capacitor tissue paper》

4、ASTM D149《Test method for dielectric breakdown voltage and dielectric strength of solid electrical insulating materials at commercial power frequencies》

Ⅲ. Scope of application

It is mainly applicable to the test of breakdown strength and withstand voltage time of solid insulating materials such as wire sleeve, resin and adhesive, impregnated fiber products, mica and its products, plastics, film composite products, ceramics and glass under power frequency voltage or DC voltage; The instrument is controlled by computer, which can quickly and accurately collect and process various data in the test process, and can access, display and print.

Ⅳ . Main technical indicators

NO. | Model (GJW) | 5KV | 10KV | 20KV | 50KV | 100KV | 150KV |

1 | Input voltage | AC220V 50Hz | AC 380V 50hz | ||||

2 | Output voltage | AC:0~5kV DC:0~5kV | AC:0~ 10kV DC:0~ 10kV | AC:0~20kV DC:0~20kV | AC:0~50kV DC:0~50kV | AC:0~ 100kV DC:0~ 100kV | AC:0~ 150kV DC:0~ 150kV |

3 | Output power | 0.5kVA | 1kVA | 2kVA | 3kVA | 10kVA | 15kVA |

4 | Measuring range | AC:0.05~5kV DC:0~5kV | AC:0.5~ 10kV DC:0.5~ 10kV | AC:1~20kV DC:1~20kV | AC:1~50kV DC:1~50kV | AC:1~ 100kV DC:1~ 100kV | AC:1~ 150kV DC:1~ 150kV |

5 | Measuring error | ≤ 2% | |||||

6 | Boosting rate | 0.025kV/s~0.5/s | 0.05kV/s~1kV/s | 0. 1kV/s~2kV/s | 0.20kV/s~5kV/s | 0.5kV/s~10kV/s | 1kV/s~10kV/s |

7 | Withstand voltage time | 0~4H (No load withstand voltage) | |||||

8 | Leakage current | 1~30 mACan be freely set by computer software | |||||

9 | Power supply | Single phase AC voltage of 220V ± 10% and frequency of 50Hz ± 1% | |||||

10 | Test environment temperature | Temperature:15 ~ 30 ℃; relative humidity: 30% ~ 65%, which can operate stably | |||||

11 | Overall dimension | L*W*H:1000*530*1380mm | 1630*1150*1970 mm | ||||

| Packed dimension | L*W*H:1200*940*1410mm | 1740*1290*1820 mm | ||||

12 | Equipment weight | 107 kg | 340kg | ||||

| Packed weight | 167 kg | 420kg | ||||

13 | Grounding requirement | The instrument needs to be grounded separately.The grounding must comply with national standards: the metal rod should be buried at least 1.5m underground. | |||||

Ⅴ. Structural principle and characteristics

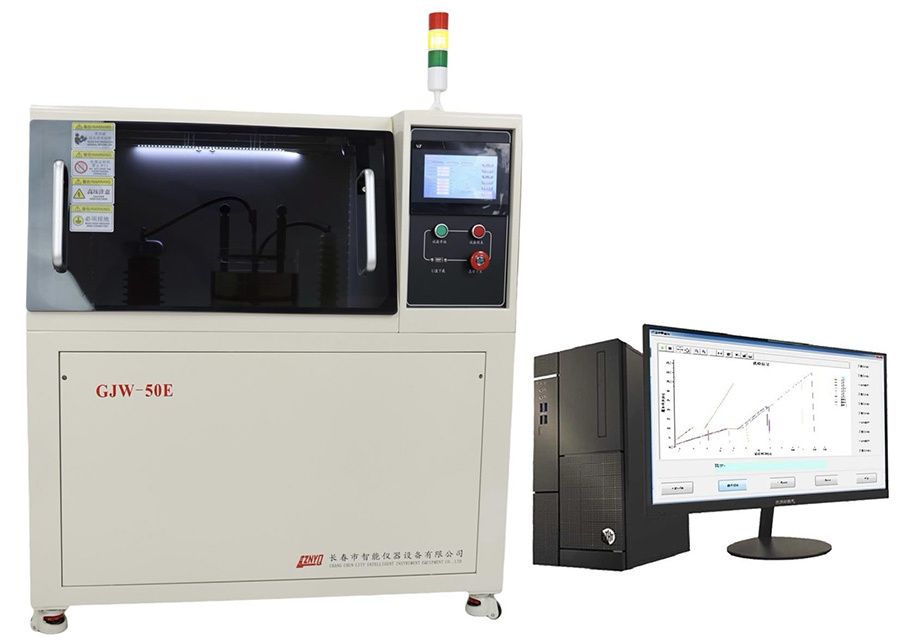

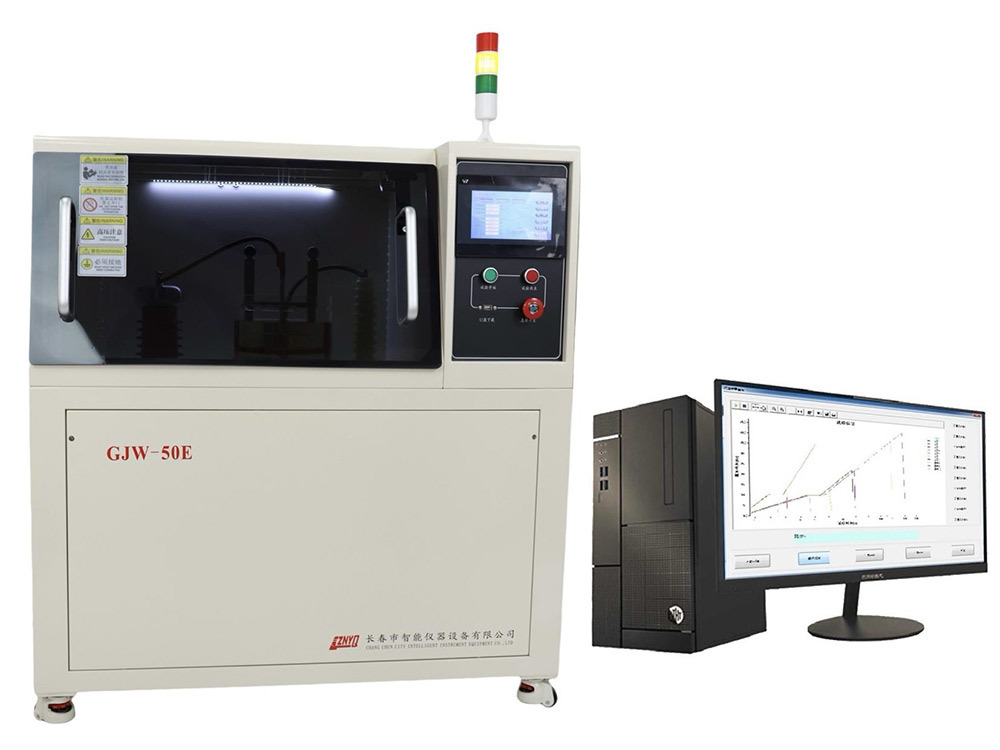

The equipment is mainly composed of:touch screen control system、Bluetooth communication system, Booster system (high voltage transformer) 、measurement system 、discharge system 、electrode 、oil tank 、 electrode positioning stand 、computer data processing system 、software, etc.

Ⅵ. Touch screen control system, computer system and software package

Touch screen control system is the latest developed by our company, with powerful function, simple operation and intuitive display. The instrument adopts touch screen control and completes the power frequency voltage breakdown and power frequency withstand voltage test of insulating medium through human-computer conversion.

Touch screen operation interface

Touch screen Download Interface

Simple parameter can be set through the touch screen to complete all tests and the test result can be exported via USB, but there will be no curve of the test process. If you need a graph, you need to connect a computer.

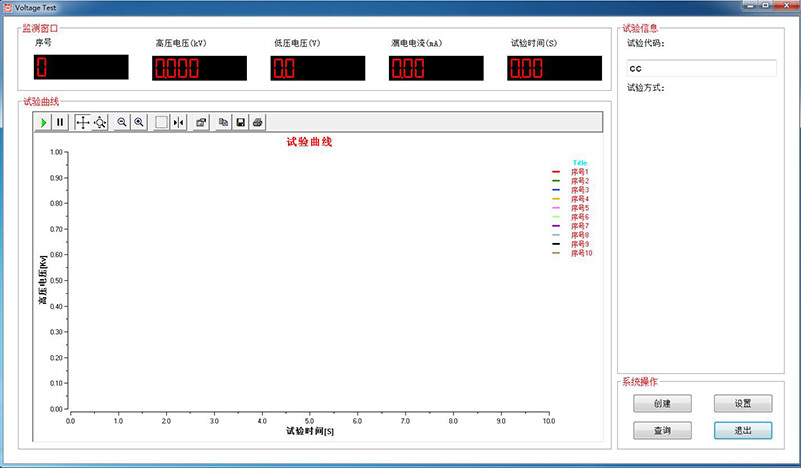

Computer main interface

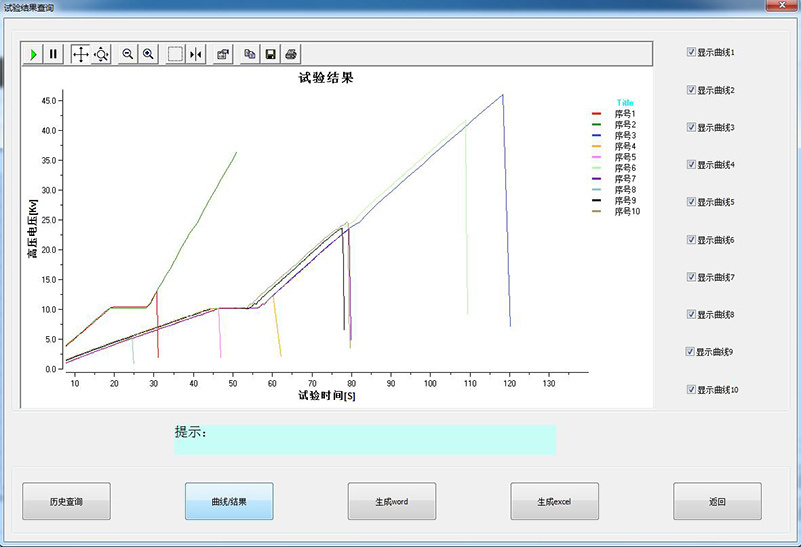

Test processing interface

1. During the test, the test curve can be drawn dynamically. The test curve can be superimposed and compared with a variety of colors and locally enlarged. Any section of the curve can be analyzed by regional amplification;

2 、The test data can be edited and modified, which is flexible and applicable;

3 、Test conditions and test results data can be stored automatically;

4 、The test report format is flexible and adaptable to the different needs of different users;

5 、The validity of curve data in a group of tests can be manually selected;

6 、Test result data can be imported into Excel and Word for editing;

7 、The overcurrent protection device has sufficient sensitivity to ensure that the power supply is cut off within 0. 1s when sample breaks down;

8 、Durability of instrument operation: the instrument can be operated continuously without regular shutdown to protect the instrument;

9 、Automatic voltage stabilization function during voltage withstand test (not affected by voltage grid voltage fluctuation).

The testing software is the latest developed by our company,with powerful functions,simple operation and intuitive display.

The instrument adopts computer control and completes the power frequency voltage breakdown and power frequency withstand voltage test of insulating medium through human-computer conversion. This instrument is the first of its kind and the patented product of our company, patent number: ZL 2017 2 1731210.3

Ⅶ. Safety instructions for high voltage breakdown equipment:

1.Separate protective ground wire should be installed for the equipment. The protective grounding wire is mainly used to reduce the strong electromagnetic interference to the surrounding when the sample breaks down;It can also prevent the computer from getting out of control.

2.DC test discharge alarm function:After the equipment has completed the DC test, the equipment will automatically alarm when the test door is opened, and the alarm will automatically cancel after the discharge device is used to discharge.(Note: It is dangerous not to discharge after DC test, the electrode cannot be taken directly. The alarm device will remind the operator to discharge so as not to cause personal injury).

3.The test discharge device, integrated with the host, improve the function of previously equipped with a separate discharge pole.

4.Safety protection:

①Door interlock protection

②Over-voltage and over-current protection

③High voltage warning light

④Emergency stop button

⑤Discharge alarm

⑥Leakage protection switch

Ⅷ. List of main configuration and key components

No. | Name | Model | Number | Manufacturer |

1 | Host machine | GJW-50E |

|

|

Contain | Boosting device | High voltage transformer | 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

Automatic discharge device |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

Measurement control system | ZNDYtest-2020 | 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

Voltage regulating device |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

Safety shield |

|

| Changchun Intelligent Instrument Equipment Co., Ltd | |

2 | Computer data processing system |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

Contain | Computer | Standard configuration | 1 | Domestic standard |

| Control software |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

3 | Test electrode | Two Φ25 and One Φ75 | 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

4 | Discharge rod |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

5 | Test oil tank |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

6 | Power line 、 grounding wire and signal cable |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

Ⅸ.Functional features:

1. Operated and controlled by the touch screen and control panel of the device itself.If curve analysis is not required, it can not be equipped with a computer.

2. If curve analysis is required, a computer can be equipped to only perform data and curve recording functions, without controlling the equipment, avoid the need for testers to alternate between the computer and equipment, make it more user-friendly.

3. The equipment has the function of test parameter memory.The same test conditions do not need to be set for each test, and even if the power is cut off, the last test setting parameters will still be remembered.

4. The test interface is simple and clear, and is equipped with schematic curve description, different parameters, different curve trends, easy to understand.

5. The control panel is simple,with clear functional labeling and easy operation.

6. It can record and display 10 test records simultaneously, facilitating comparative analysis of test data, and any set of data that isn’t ideal can be discarded at any time.

7. Added USB download function,which can download the test records in the device directly to the USB.

8. If equipped with a computer, a detailed test report can be generated, including each group of specific information,multiple groups of comprehensive information and curves.

9. The equipment testing interface adopts a dashboard and digital display mode that is both simultaneously and real-time, making it more convenient to observe the testing process.

10. The equipment has safety warning prompt, the test cannot start without closing the test chamber door, and a warning will pop up and the warning will pop up when the full degree (i.e. no output from the high-voltage transformer), and the test will automatically end if the door is opened during the test.

11. Using Bluetooth data transmission to solve the problem of being blocked by isolation walls, remote operation is safe and reliable.

12. The equipment is equipped with three color alarm light. When the green light is on, it indicates that the chamber door is closed well and the test can start; when the yellow light is on, it indicates that the chamber door is open and the sample can be replaced; when the red light is on, it indicates that the high voltage is higher than 0.5kV and the chamber door shouldn’t be opened at this time. The warning light will flash and sound an alarm during the discharge process after the DC test is completed. ( Green light:The chamber door is closed properly; Yellow light: Be careful when opening the door; Red light: There’s high voltage)

Keywords

GJW-50E Touch screen controlled voltage breakdown tester

Contact Us

Classification