Ⅰ 、Compliant standards

GB/T1411-2002 《 Dry,solid insulating materials-Resistance test to high-voltage, low-current arc discharges》 (Equivalent to IEC 61621-1997) and ASTM D495 and other standards ;comply UL 746Aand other test methods.

Ⅱ 、Application

NDH-15K Arc resistance test system is a high precision equipment specially developed for the test of electrical insulation materials ,it’s suitable for electric insulation materials, plastics, film, resin, mica, ceramics, glass, insulating paint and other insulating materials arc resistance evaluation,it can also be used in product testing and research of electrical properties of new materials.

Ⅲ 、Functional principle

Insulation materials have the ability to resist deterioration caused by high voltage arc action , usually a standard arc flame is used to induce carbonization on the surface of the material until the surface is conductive.The time required for the arc to disappear is expressed in second. Add two tungsten electrodes separated by a certain distance on the plate sample, at first the arc is intermittent, then gradually shortened,and finally continuous arc with gradually increasing current,the material is subjected to increasingly severe arc conditions and eventually fails.Arc resistance is important for insulating materials used in high-voltage switches or low-voltage high-current switches,because the switch is often affected by arc when it is opened and closed, only materials with good arc resistance can be selected.

Insulating material used in the interior of electrical and electronic equipment, when exposed to a

high-voltage, low-current arc discharge, is tested the differences in surface damage close to the arc.The arc discharge causes local thermal and chemical decomposition and corrosion and eventually forms a conductive channel on the insulating material ,When a conductive channel is formed in the tested

material, the material can be determined to have failed.

Arc resistance tester is GB1411, IEC61621, ASTMC495, UL746A and other standards of the simulation safety test project necessary special instrument.

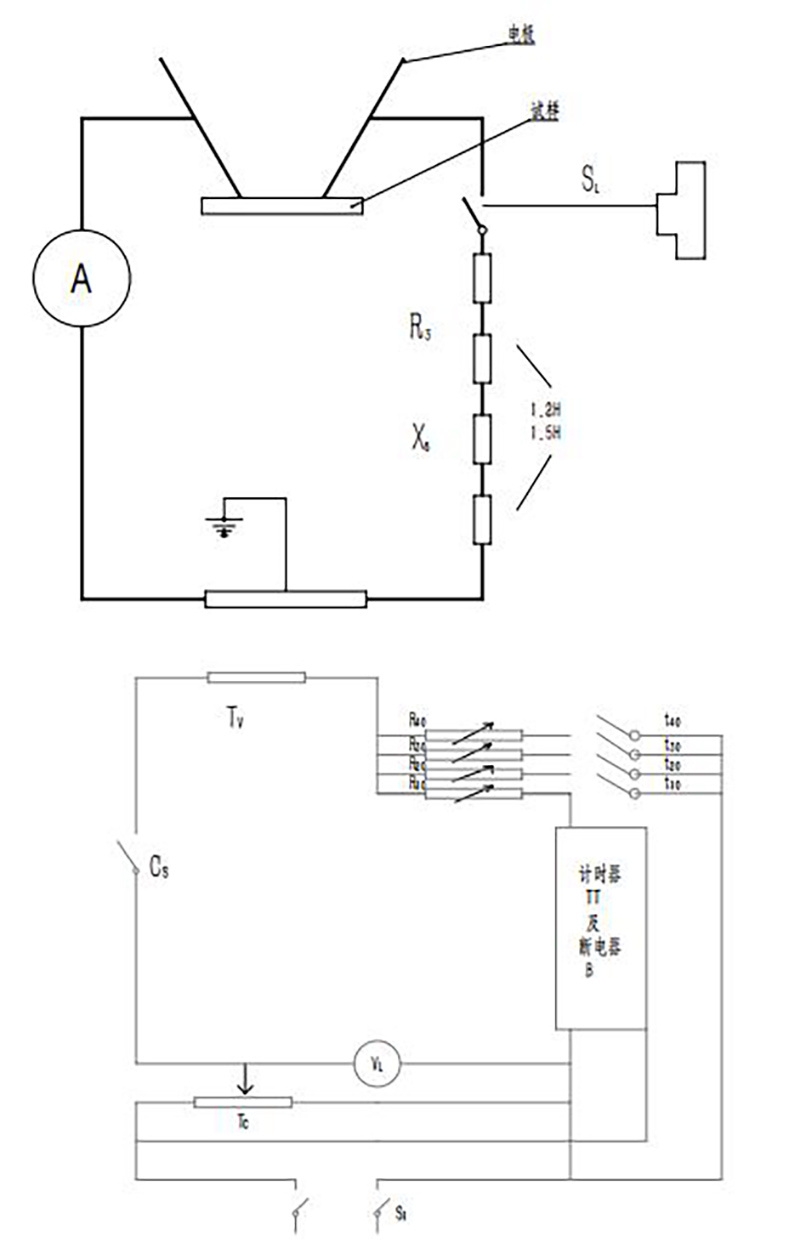

The arc resistance tester is composed of electrical schematics and electrodes according to the following standard requirements

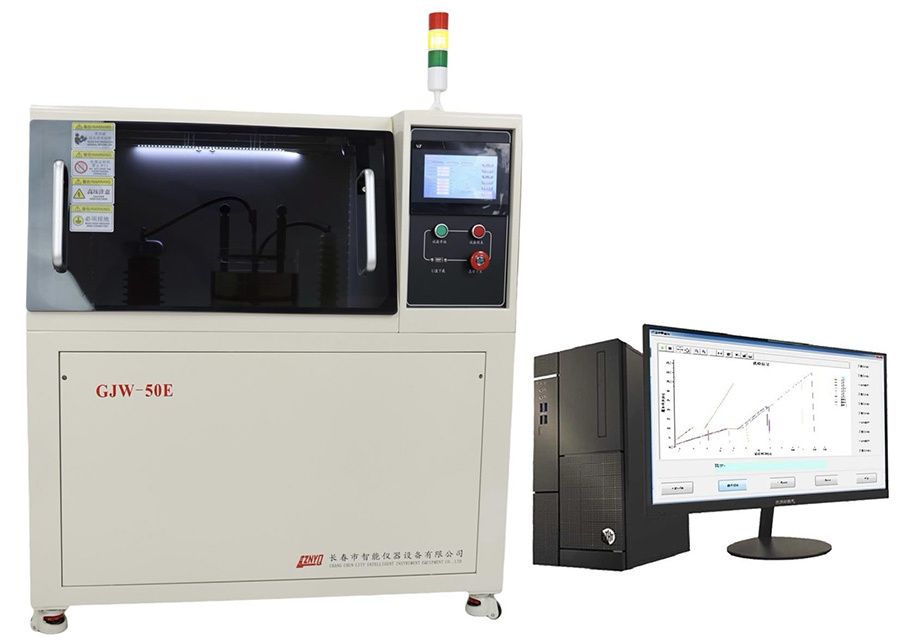

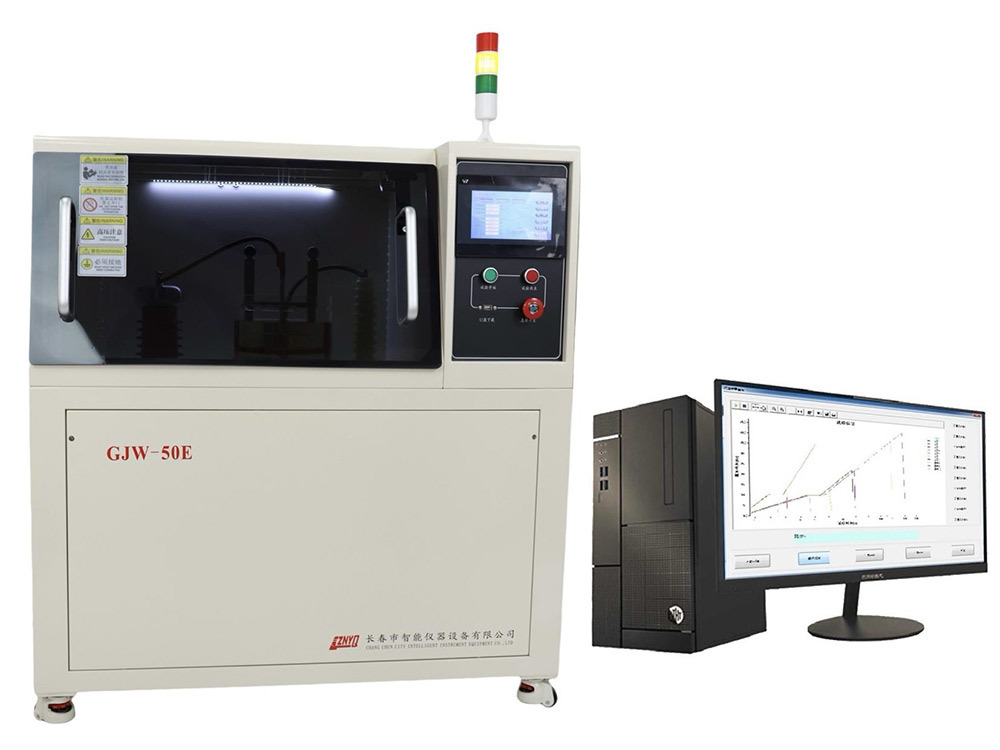

Structure and Composition

The system consists of two parts

(1)Control section:The lower part of the arc resistance tester is the operating system ,internal electrical control system, test can be performed automatically by selecting a program,and the digital

display of each test process and results, test start, stop, breakdown and trip protection, test termination judgment.

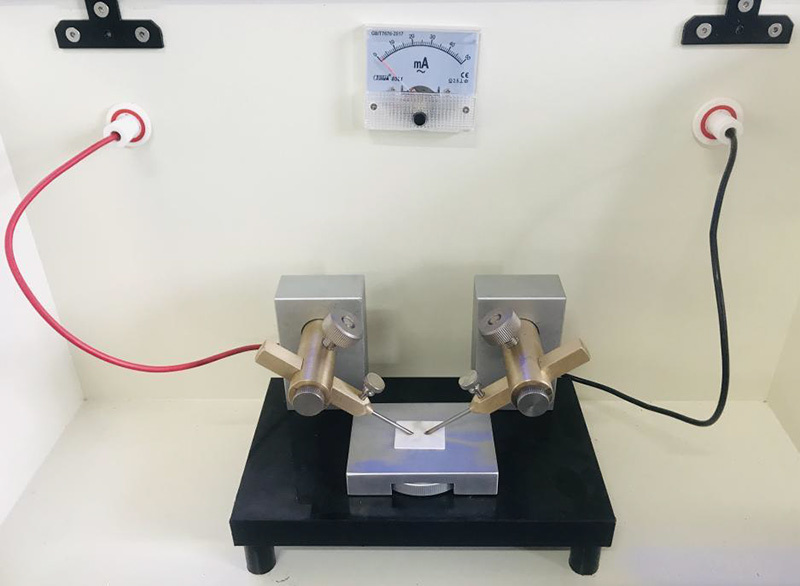

(2)High pressure test section:It consists of electrode system

Figure 1

The electrode material is tungsten rod ,diameter 2.4mm±0.05mm, The Angle between the ellipse tip surface and the axis is 30°±1° ,

A force of 0.5N±0.05N is applied to the sample

The two electrodes are tilted horizontally 35°±1°(The Angle between the axes is 110°±2°) ,

Two tip spacing:(6.35±0. 1)mm(IEC)

(6.00±0. 1)mm(ASTM)

This product uses single chip microcomputer and touch screen control, high degree of automation, can automatically regulate the voltage,automatically switch the execution program, automatically describe the running curve, measure the real-time voltage and current, and time the test time.

The electrode system imitated the German imported electrode, Angle, gap calibration is convenient, fast and efficient, it has good repeatability and high precision

Data measurement using high precision, high-speed conversion chip, fast conversion speed, high measurement precision, strong anti-interference ability.

Figure 2

With the shield closed, the voltage is applied and the current is regulated by variable resistors R10, R20, R30 and R40 to observe whether the sample forms a conductive channel. See figure1 R10 、R20、 R30 、R40.

Ⅳ 、Scope of application

PCB

Photovoltaic film materials

Ptfe, ABS, nylon and other plastics

Film material

Insulating paint Mica materials

Ceramic, glass fiber, etc

Ⅴ 、Equipment parameter

1 、Arc on/off time error: All program segments are superior±1ms

2 、Voltage regulator capacity:1kVA

3 、Rated test voltage:12.5kV

Maximum test voltage:15kV

4 、Test voltage accuracy:<1.5%

5 、Current measurement accuracy:<1.5%

6 、Electrode pressure on sample:(0.5±0.05)N

7 、Electrode material:Tungsten bars

8 、Distance between electrodes:(6.35±0. 1)mm(IEC) (6.0±0. 1)mm(ASTM)

9 、Ambient temperature:(23±2)℃

10 、Ambient humidity:(50±5)%

11、Power supply:220V±5% 50Hz 10A

12 Equipment weight:58kg Packed weight:80kg

13 Equipment dimension:(L*W*H)670*660*590mm Packed dimension:780*770*830mm

Program segment | Arc current mA | Arc on&off time /s | Duration of each program segment/s | Total test time/s | |

IEC 61621 | ASTM D495 | ||||

1 | 10 | 1/8son 7/8s off | 1/8son 7/8s off | 60 | 60 |

2 | 10 | 1/4s on 3/4s off | 1/4s on 3/4s off | 60 | 120 |

3 | 10 | 1/4s on 1/4s off | 1/4s on 1/4s off | 60 | 180 |

4 | 10 | Continuous power on | 60 | 240 | |

5 | 20 | Continuous power on | 60 | 300 | |

6 | 30 | Continuous power on | 60 | 360 | |

7 | 40 | Continuous power on | 60 | 420 | |

Ⅵ 、Standard Configuration

1 Arc resistance tester host machine 1

2 Electrode system 1 set

3 Power cable 1

4 Standard electrode spacing measure block 1

5 Angle standard block 1

6 Product Ex-factory report 1

7 Sample stand 1

8 Operation instruction 1

9 Packing list 1

Note:All instruments and equipment need to be grounded and the grounding resistance is ≤4Ω . , The supply and demand sides agree that the supplier should provide technical requirements and the demander should build the grounding system by itself.

Keywords

NDH15K Arc resistance tester

Contact Us

Classification