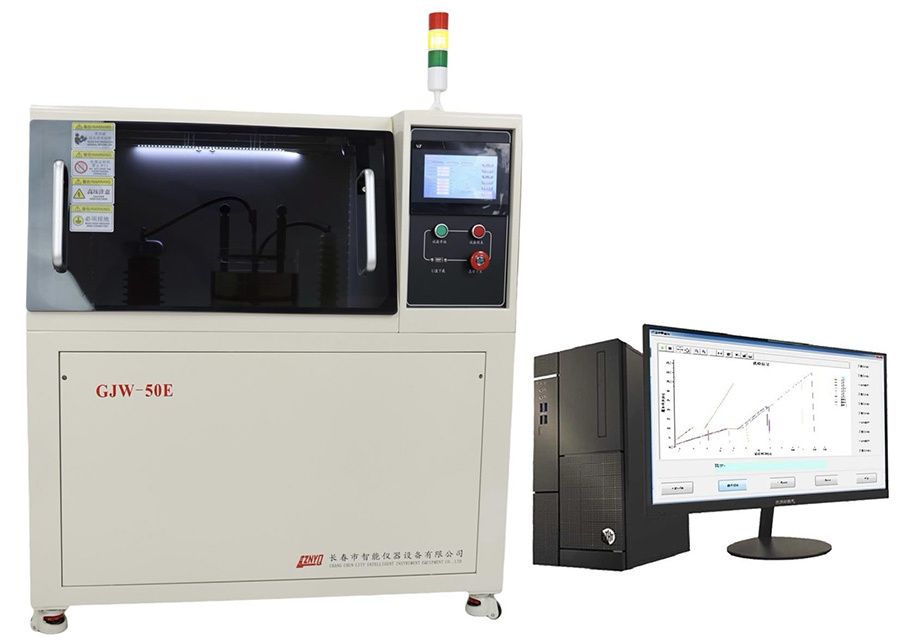

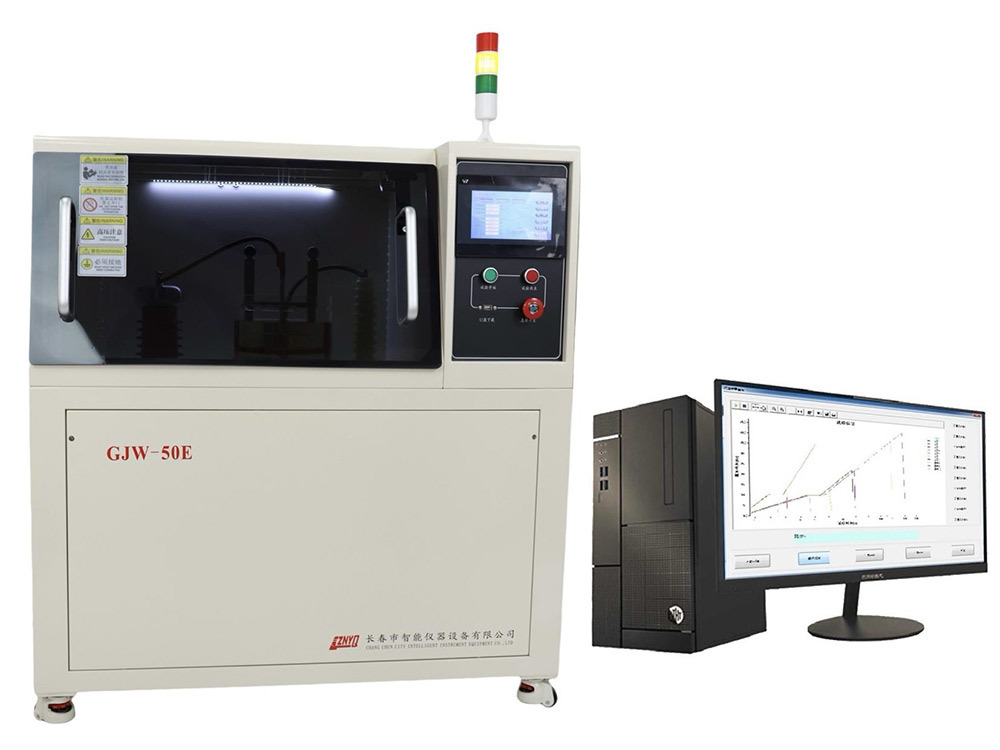

Ⅰ 、Scope of application

It is used to study the thermal stability, shear stability, flow and plasticizing behavior of thermoplastic materials ,It can continuously, accurately and reliably measure the rheological properties of the system in a process similar to the actual processing, and can also complete the curing characteristics test of thermosetting materials. The conical twin screw extruder is composed of main control unit and conical twin screw unit, which can simulate the production process of conical twin screw extruder in laboratory. With the help of different molds, it can directly extrude plates, pipes and profiles for experiments.

Ⅱ 、Technical specification:

1 、Mobile measurement and control host platform

Control mode:Industrial bus

Installation:Split installation

Operating system:Windows 7

Electric motor:Japan Panasonic

Power:5.0kw

Electric motor speed:2000 rpm

Electric motor controller:5.0 kw

Reducer:China Hubei Kefeng

reduction ratio:10:1

Power output rotating speed:0.1 ~ 200 r/min

Rotating speed control accuracy:0 .05%F.S

Torque measurement method:Cantilever dynamic torque measurement

Torque measurement range:0 ~240Nm

Torque measurement accuracy:0. 1%F.S

Dynamic temperature control accuracy:± 0.5°C

Dynamic temperature control accuracy:± 0.1°C

Temperature control:5 temperature measurements, with 4 temperature control channels.

Melt pressure measurement range:0.1 ~ 100 Mpa

Melt pressure measurement accuracy:0.5 % F.S

Software:Polymer melt viscosity measurement data processing software

2、Movable cone-type twin-screw extrusion platform

Screw barrel separation structure:Pull out rotary type

Screw type:Two-cone type

Screw material:38CrMOALA

Screw diameter:20/40 mm

Heating method:Electric heating

Effective length of screw:325mm

Double tube screw barrel:20-40mm

Temperature control system:Taiwan Delta

Max temperature:350℃

Temperature sensor:T-type thermocouple

Total heating power:3.2 kW

Heating zone:4 zones

Type of cooling:Air compression

Feeding adjustment:Manual

Feed method:Volumetric feeder

Output:1 -10 kg/ h

Mold: Broadband mold: thickness 1.5mm, width 60mm

Ⅲ、Software configuration

Software configuration and functions | ||

Name of software | Function | Features |

Control software | Instrument operating platform | 1.Virtual control interface 2.Easy to operate 3.High control accuracy |

Ⅳ 、Other technical requirements

1 、Power data and environmental requirements

● Low voltage supply standard:380V

● Control voltage standard:220V

● Ambient temperature requirement:10-40℃

● Air relative humidity requirements:max.80%,without condensation

● Flatting ground

2 、Contents of documents provided by the supplier

● Operating instruction

● Product certification

● Product packing list

● Product software CD

Ⅴ 、Main configuration

No. | Name | Model | Number | Manufacturer |

1 | Measurement and control host | ZJL series |

| Changchun Intelligent Instrument Equipment Co., Ltd |

Contain | Drive electric motor and driver | MDME series MFDHT series | 1 | Japan Panasonic |

Reducer | VRB series | 1 | China Hubei Kefemg | |

Torque sensor | LZ-HLA | 1 | China Hefei Lizhi | |

Control and measurement module | DTE | 5 | Delta | |

Measurement and control system(including pressure, temperature, torque, rotating speed, amplifier circuit, etc.) |

ZNLB-2015 |

1 |

Changchun Intelligent Instrument Equipment Co., Ltd | |

3 | Conical twin screw extruder |

|

| Changchun Intelligent Instrument Equipment Co., Ltd |

| Double tube screw | 20mm-40mm |

| Changchun Intelligent Instrument Equipment Co., Ltd |

| Die head | Sheet die head 1.5*60mm | 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

4 | Test software |

|

| Changchun Intelligent Instrument Equipment Co., Ltd |

| Extruder data processing software |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

6 | Computer controlled system |

|

|

|

Contain | Brand computer | Standard | 1 | Domestic brand |

Keywords

ZSJ-20/40 Conical twin-screw extruder Technical data

Contact Us

Classification