Temperature control module

Ⅰ 、Scope of application:

Torque rheometer is an ideal equipment to study the flow and deformation, plasticization, thermal shear stability, dynamic rheological properties and plasticization behavior of polymer materials and show the results in the form of torque-time and torque-temperature,and the mixing of multi-component materials, the cross-linking curing of thermosetting resins, the vulcanization of elastomers, the dynamic stability of materials and the influence of screw rotating speed on the processing performance of the system, etc. It can be widely used in scientific research and production, laboratory simulation in the mixing, extrusion process, a series of data to guide the reality of formula research and production, can be similar to the actual processing, continuous, accurate, reliable to determine the rheological properties of the material.

Ⅱ 、Product features:

It has modular design and ready-to-use function: the host is the control center, which has the function of driving and controlling the measuring unit; the controlled auxiliary units (such as mixing units and extrusion units) are intelligent measuring units for specific applications, which can transmit the measurement data to the host through the bus system. It can be equipped with various auxiliary units to complete laboratory simulation experiments for different purposes.

Ⅲ. Application area

1 、UPVC processing performance research and material development

2 、Development and processing properties of thermoplastic materials

3 、Thermoplastic material development and processing performance research

4 、Teaching and scientific research application

Ⅳ. Performance parameter

4.1 、Host machine

4.1.1 、Motor power (Panasonic motor, controller): 3.0kW

4.1.2 、Motor rotating speed: 2000r/min

4.1.3 、Reduction ratio (China Hubei Kefeng reducer) 15:1

4.1.4 、Rotating speed range: 0.1~ 120 rpm

4.1.5 、Speed control accuracy: ±0.2%F.S..

4.1.6 、Torque measurement range: 0 ~ 200Nm(Rated torque 300Nm)

4.1.7 、Torque measurement accuracy: ±0.3%F.S.

4.1.8 、Melt pressure measurement range: 0.1~ 100Mpa (It can be customized according to user requirements, and the price negotiable.)

4.1.9 、Pressure measurement accuracy:+0.3 %F.S.

4.1.10 、Temperature control range:Room temperature~350℃ (five-way temperature control)

4.1.11、Temperature control accuracy:+0.5℃

4.1.12 、Graphic display: Rotating speed, torque, temperature, pressure

4.1.13 、Voltage:AC380V 7.5kw Measurement and control software:

4.1.14、Data acquisition rate:50/S More subtle changes in torque, temperature and speed can be recorded

4.1.15 、High speed acquisition.The temperature torque data curve can be amplified to observe the real-time transition change.

4.1.16 、Polymer melt viscosity measurement data processing software

4.1.17 、Extruder data processing software

4.1.18 、Mixer data processing software

4.1.19 、Equipment dimension:(L*W*H)900*440*1130mm Packed dimension:1060*770*1590mm

4.1.20 、Equipment weight:105kg Packed weight:135kg

4.2 、Mobile mixer(60ml)

4.2.3 、Mixer capacity:60ml

4.2.4 、Material:4Cr13

4.2.5 、Rotor type:Roller 、 Standard (Matching of Banbury 、Cam 、Delta ,Sigma)

4.2.6 、Rotating speed ratio:3 :2

4.2.7 、Max temperature:350℃

4.2.8 、Max torque:200Nm

4.2.9 、Heating method:Electric heating

4.2.10 、Temperature sensor:K-type thermocouple

4.2.11、Heating zone:3way(4 way temperature measurement)

4.2.12 、Heating power per sheet:700W*3=2100W

4.2.13 、Equipment dimension:(L*W*H)700*420*1450mm Packed dimension:980*750*1340mm

4.2.14 、Equipment weight:92kg Packed weight:117kg

4.3 、 Mobile mixer(200ml)(Optional)

4.3.1 、 Mixer capacity:200ml

4.3.2 、 Material:4Cr13

4.3.3 、 Rotating speed rate: 3 :2

4.3.4 、 Max temperature: 350℃

4.3.5 、 Max torque: 250Nm

4.3.6 、 Heating method: Electric heating

4.3.7 、 Temperature sensor: K-type thermocouple

4.3.8 、 Heating zone: 3way(4way temperature measurement)

4.3.9 、 Total heating power: 2.5KW

4.3.10 、 Rotor type: Roller (Standard) / Banbury 、Cam 、Delta ,Sigma (Optional)

4.4 、 Plastic single screw extruder(Material 38CrMOALA)

4.4.1 、L:D: 25:1

4.4.2 、Screw diameter: φ20mm

4.4.3 、Screw compression ratio:2.5 :1

4.4.4 、Max temperature: 350℃

4.4.5 、Heating method: Electric heating

4.4.6 、Heating zone: 5way

4.4.7 、Total heating power: 4200W

4.4.8 、Temperature sensor: K-type thermocouple

4.4.9 、Equipment dimension(L*W*H):1600×450×1300(mm)

4.4.10 、Capillary mold:φ1.27 L:D 20:1 、30:1 、40:1 (one mold core each) (φ1 、φ2 Other specifications can be selected)

Cylindrical die head (optional):Inner Diameter:Ф5 ,Outer Diameter: Ф10

Ⅴ 、Main configuration

No. | Name | Model | Number | Manufacturer |

1 | Measurement and control host | ZJL200A |

| Changchun Intelligent Instrument Equipment Co., Ltd |

Contain | Drive electric motor and driver | MDME series MFDHT series | 1 | Panasonic |

Reducer | VRB series | 1 | China Hubei Kefeng | |

Torque sensor | Cantilever high precision | 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

Temperature control module | DTE | 5 | Delta | |

Measurement and control system (including pressure, temperature, torque, rotating speed, amplifier circuit, etc.) |

ZNLB-2015 |

1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

2 | Mixing unit | Standar 60ml |

| Changchun Intelligent Instrument Equipment Co., Ltd |

Contain | Heating plate (including heating element) |

| 3 | Changchun Intelligent Instrument Equipment Co., Ltd |

Material pressing device |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

Rotor | (Roller-type) | 2 | Changchun Intelligent Instrument Equipment Co., Ltd | |

Gear box |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

3 | Extruder unit |

|

|

|

Contain | Single screw | (L:D 25:1) | 1 | China Zhejiang |

Screw cylinder |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

Charging hopper |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

Heating device | 5way | 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

Screw centering device |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

4 | Single screw mold | Capillary mold Inner Diameter 1.27mm |

|

|

Contain | L:D :20:1 |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

L:D:30:1 |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

L:D:40:1 |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

Cylindrical die head | Outer Diameterφ10、 Inner Diameterφ5 | 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

5 | Test software |

|

| Changchun Intelligent Instrument Equipment Co., Ltd |

Contain | Polymer melt measurement data processing software |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

Extruder data processing software |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

Mixer data processing software |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd | |

6 | Computer-control system |

|

|

|

Contain | Brand computer | Standard configuration | 1 | Domestic brand |

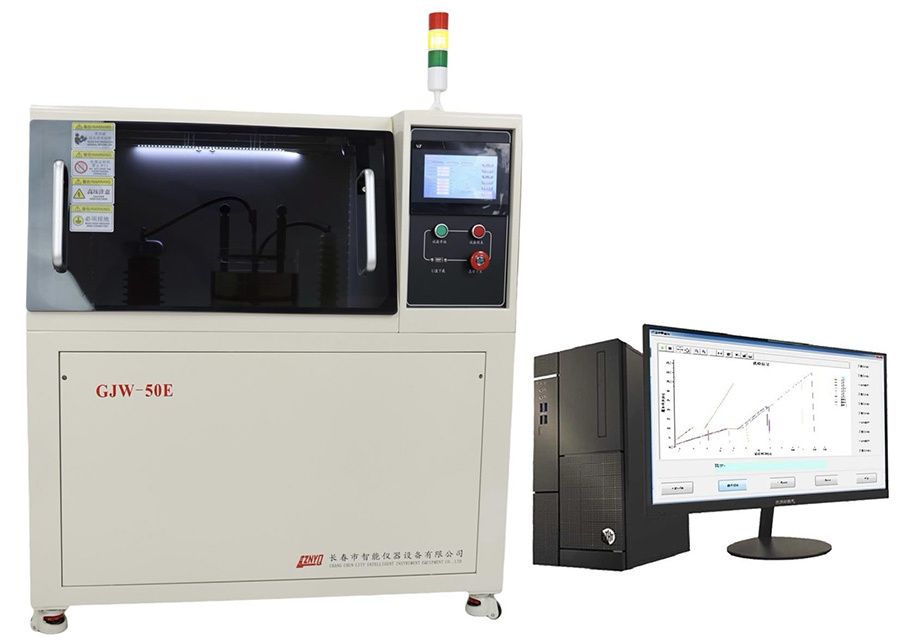

Ⅵ 、Structure principle and performance characteristics

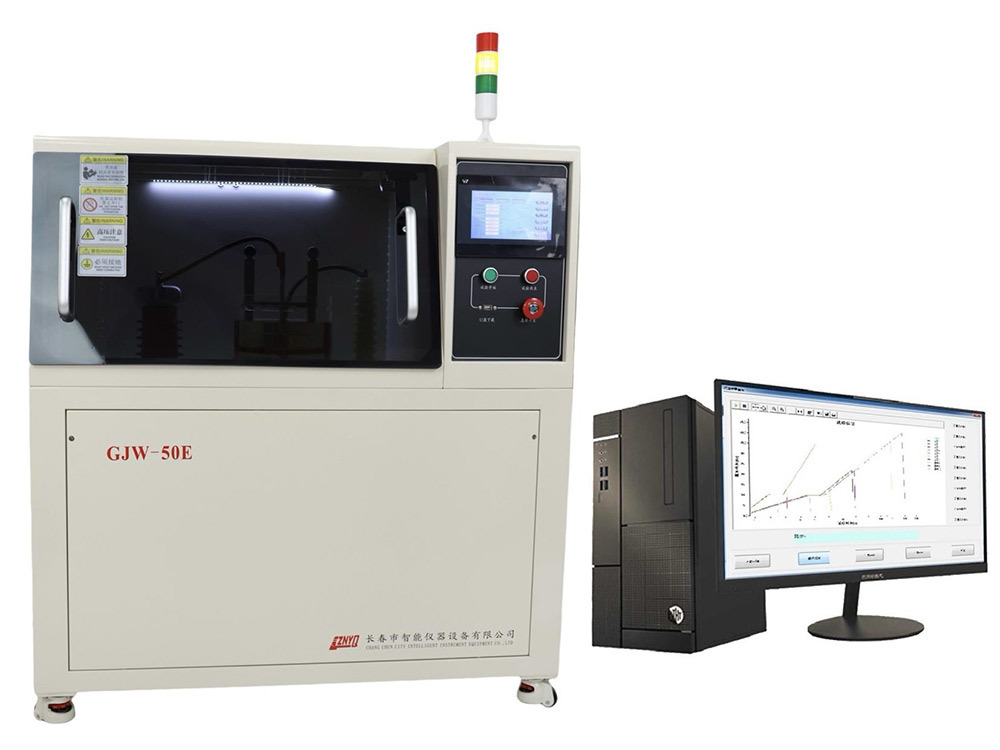

1)Structure and composition:A main measurement and control host is independently connected with the mixer or single-screw extruder or twin-screw extruder under different requirements to form two modes ; mixing rheometer and extrusion rheometer, which can be identified by the program.

ZJL series torque rheometer, in addition to the main part of the host, extruder, mixer, computer, can also be equipped with automatic weighing unit, measuring unit, three-roll calender, screw extruder, film blowing machine, strip sample calender and traction unit test unit.More testing can be done with these units.

1、Automatic weighing unit:It can automatically measure the relationship between apparent viscosity of the material and shear rate and shear stress.

2 、Diameter measuring unit:Complete the automatic measurement of die expansion.

3 、Strip specimen calendering and traction unit.It can be made into uniform strip specimen for tensile and thermal extension tests.

The above optional unit (the general configuration does not include the above unit) can be composed of the measurement and control host and computer as the core and other components, respectively, to form a different test system.

Host machine:It is mainly composed of body, drive electric motor and driver, reducer, torque sensor, temperature control system, measurement and control system, computer data processing system, etc.

1 、Japan Panasonic drive electric motors and drives

2 、Domestic planetary reducer

3 、Temperature control system

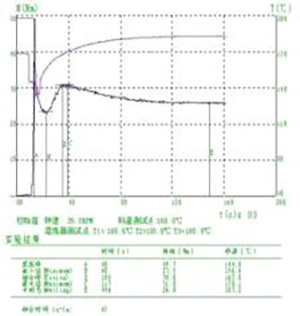

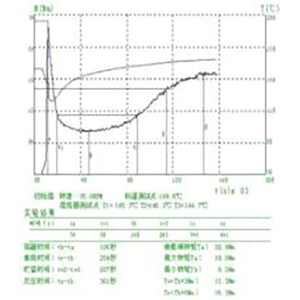

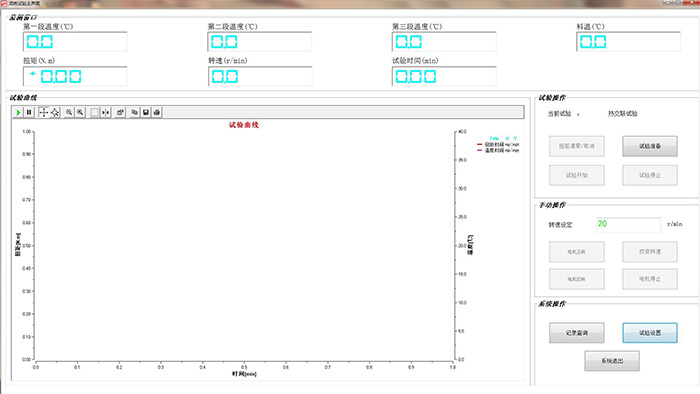

2)System software

The supporting software set consists of Mixer -- mixer test and control software, Plastic -- extruder test and control software, WinNian -- apparent viscosity test data processing software. Mixer and Plastic software interface has rich functions, which can complete the measurement, setting and control of rotating speed, torque, temperature and pressure, and the curve window can display the curve of the above data versus the time in real time.These data can be processed and mapped by software, test and control software to form an test report, and output by color printer. It also has the functions of multiple curve superposition and smooth curve processing.

ZJL-200 torque rheometer is an automatic test instrument with computer as the core. Data acquisition, control and test data processing are completed by the relevant software.

This not only shows that the instrument is easy to operate, the control is accurate, the experimental data processing and the result output are fast and efficient 。More importantly, with the support of the software, it can complete the functions that the traditional torque rheometer cannot complete.For example, linear acceleration measures the shear-sensitive properties of a material.Calibration of the die during the measurement of the relationship between apparent viscosity and shear rate of materials.The design idea of ZJL-200 torque rheometer is to achieve function expansion and performance improvement through software development on the basis of minimizing the increase of hardware equipment, so it has a high cost performance.

Test software operating interface

Mixer and its application

The chamber of the mixer of ZJL-200 torque rheometer adopts a

three-piece structure,electric heating,rotational speed ratio 3:2,The volume after adding the rotor is 60ml, Made of stainless steel material, good corrosion resistance ,The mixer can be used to perform many tests, such as PVC material thermal fusion test, thermosetting material curing crosslinking performance test, thermal stability test, shear sensitivity test, etc.

Mixer

Rotor

Test curve superposition report

Plastic extruder and apparent viscosity test

The screw length-diameter ratio of the plastic extruder is 25:1 ,Optional granules and powder screws with different compression ratios, combined with capillary extrusion dies, cylindrical extrusion dies, tube extrusion dies, wire coating dies, etc. to conduct simulation experiments of different processes.The relationship between apparent viscosity and shear rate and shear stress can be measured by capillary extrusion die.

Productization and application status

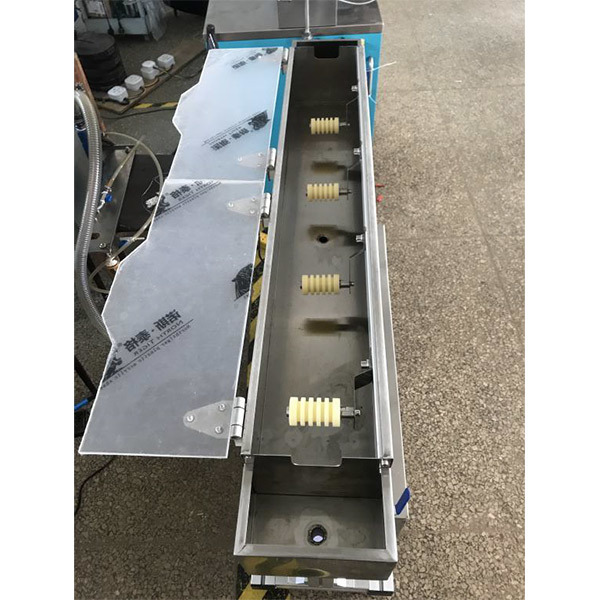

Cooling tank(Optional)

The cooling water tank can directly cool and shape the extruded hose and sheet in the extruded torque rheometer with ribbon mold

Cooling method | Water circulation |

Number of idlers | 4 |

Number of idler slots | 5 |

Flow | 12000L/h |

Total power | 0. 1KW |

Power supply | AC220V |

Weight | 150kg |

Dimensions (L*W*H) | 1250x370x(1000-1200 adjustable)(mm) |

Granulator(Optional)

The machine cuts plastic strips into a granular material for experimental research

Cutter head electric motor power | 1. 1kW |

Traction wheel electric motor power | 60W |

Cutter diameter | 90mm |

Cutting size | 0.3-2.35mm |

Rotating Speed of Cutter | 940r/min |

Cutting speed | 5.65m/min |

Weight | 150kg |

Dimensions (L*W*H) | 550x470x1050mm |

Keywords

ZJL-200A Torque Rheometer

Contact Us

Classification