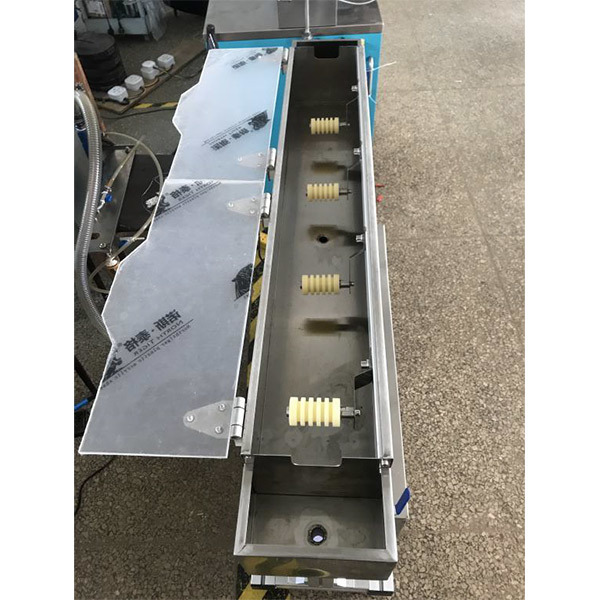

Screw barrel

Ⅰ 、Scope of application

Torque rheometer is an ideal equipment to study the flow and deformation, plasticization, thermal shear stability, dynamic rheological properties and plasticization behavior of polymer materials and show the results in the form of torque-time and torque-temperature ,and the mixing of multi-component materials, the cross-linking curing of thermosetting resins, the vulcanization of elastomers, the dynamic stability of materials and the influence of screw rotating speed on the processing performance of the system, etc. It can be widely used in scientific research and production, laboratory simulation in the mixing, extrusion process, a series of data to guide the reality of formula research and production, can be similar to the actual processing, continuous, accurate, reliable to determine the rheological properties of the material.

Ⅱ 、Product function

It has modular design and ready-to-use function: the host is the control center, which has the function of driving and controlling the measuring unit; the controlled auxiliary units (such as mixing units and extrusion units) are intelligent measuring units for specific applications, which can transmit the measurement data to the host through the bus system. It can be equipped with various auxiliary units to complete laboratory simulation experiments for different purposes.

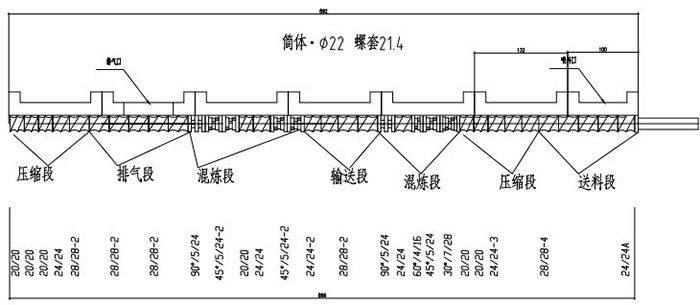

Ⅲ 、Instruction of Building Block Parallel Twin Screw Extruder

Building Block Twin Screw:It is composed of screw elements with different numbers and functions, which are installed on a keyed or hexagonal mandrel according to certain requirements and sequence. According to the processed materials and different process requirements, different quantities and different types of screw components and their best combinations can be selected for extrusion processing. In this way, limited screw elements can be used to meet different requirements through different combinations, thus solving the contradiction between the versatility of processing needs and the specificity of the machine.

(1) Screw combination

The screw of twin-screw extruder generally adopts building blocks or combined types in mechanical structure.This makes the screw configuration, barrel structure, length-diameter ratio, the position and number of the feeding port and vacuum exhaust port of the twin-screw extruder need to be adjusted according to the changes in the material system and process requirements, in order to achieve the unity of universality and specificity.

Twin-screw extrusion process: feeding, solid conveying, melting, mixing, exhaust, conveying and other functional segments。

Different functional sections require different local screw configurations to adapt to them and achieve different functions. The design of screw combination configuration is an important and difficult issue, because it is related to many factors, such as the properties of the processed materials and the formulation design, the operating conditions and the performance of the screw elements. This combination is also a special technology and know-how. There is no formula to follow. Generally, it is necessary to understand the performance of various screw elements and material properties, and design through a combination of experience, theory and experiment.

(2)Screw elements

If the material conveying process in a twin-screw extruder is divided into solid conveying zone, melting zone and melt conveying zone like the conveying process in a single-screw extruder, then corresponding to the phase change of the material during the extrusion process, a whole screw can be decomposed into different functional segments, and different functional segments use the same geometric structure to complete their functions. The screw segments that can achieve different functions are called screw elements. According to the different functions achieved, screw elements can be divided into conveying elements (composed of forward thread elements, with different numbers of screw heads and leads), pressure building elements (mainly reverse thread elements), shearing elements (kneading disks and their combinations), mixing elements (mainly toothed disk elements), etc.

Building block threaded element

Ⅳ 、Performance parameter

4.1 、Measurement and control host

Electric motor power (Panasonic electric motor 、controller) | 5.0kW | Torque measurement accuracy | ±0.3%F.S. |

Electric motor rotating speed |

2000r/min | Melt pressure measurement range | 0. 1~ 100Mpa(Can be customized according to user requirements) |

Reduction ratio | 10:1 | Pressure measurement accuracy | +0.3 %F.S. |

Range of rotating speed | 0. 1~200 rpm | Temperature control range(Five-wa y temperature control) | Room temperature~350℃ |

Speed control accuracy | ±0. 1%F.S. | Temperature control accuracy | +0.5℃ |

Torque measurement range | 0 ~ 200Nm (Rated torque 300Nm) | Graphical display | Rotating speed, torque, temperature, pressure |

Voltage | AC380V 7.5kw |

|

|

Host dimension(L*W*H) | 1060*650*1540 mm | Host weight | 225kg |

Packed dimension(L*W*H) | 1100*790*1610 mm | Packed weight | 255kg |

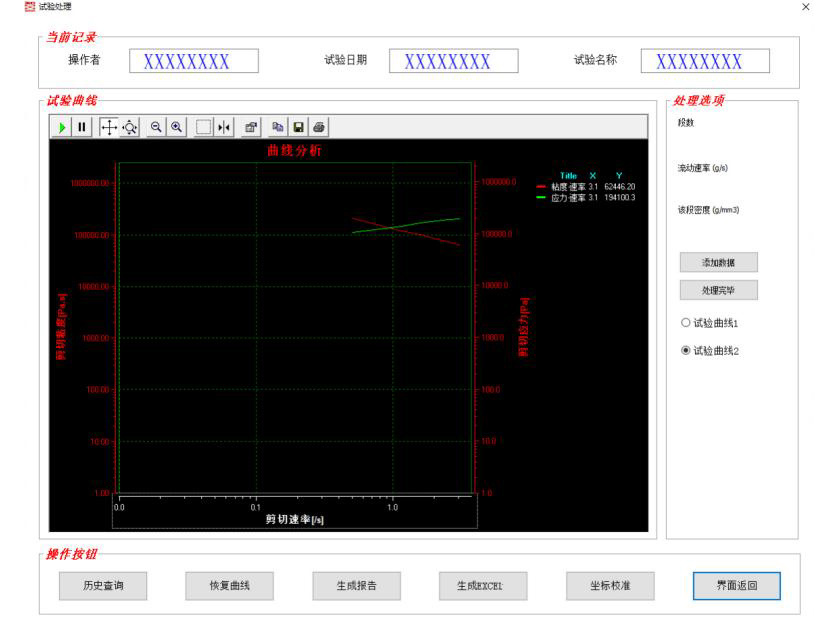

Measurement and control software:

4.1.14、Data acquisition rate:50 times/s, recorded more subtle changes in torque, temperature and speed

4.1.15 、High speed acquisition, the temperature torque data curve can be amplified to observe the real-time transition change

4.1.16 、Polymer melt viscosity measurement data processing software

4.1.17 、Extruder data processing software

4.1.18 、Mixer data processing software

4.2 Building block parallel twin screw extruder

Screw type | Parallel opposite direction twin screw | L/D | 40:1 |

Screw diameter | 22 mm | Screw groove depth | 3.5mm |

Temperature control | 8 way for temperature measurement,7way temperature control | Max rotating speed of screw |

500r/min |

Temperature control accuracy | ±0.5%F.S | Temperature range | Room temperature 350℃ |

Temperature sensor | K-type thermocouples | Heating method | 7 stage electric heating |

Total heating power | 5500W | Cooling method | Air compression |

Feeding method | Screw type metering feeding | Exhaust form | Vacuum exhaust |

Twin-screw extruder dimensions (L*W*H) | 1710*760*1370mm | Twin-screw extruder weight | 230kg |

Packed dimension(L*W*H) | 1850*800*1550mm | Packed weight | 270kg |

Twin-screw module quantity statistics(2) | ||

Function | Number of sections | Number of modules |

Feeding section | 2 | 10 |

Compression section | 4 | 20 |

Mixing section | 4 | 24 |

Conveying section | 2 | 8 |

Exhaust section | 2 | 10 |

Screw module distribution diagram(1)

4.3 Twin-screw touch computer

Brand | TSINGHUA TONGFANG |

System | win10 |

Internal storage | 4G |

Touch screen brand | Huachuang |

Touch screen type | Capacitive screen |

Touch screen size | 15.6 inches |

4.3 Mobile mixer(60mL/200mL)

Mixer capacity | 60mL / 200mL | Material of mixer | 4Cr13 |

Rotor type | Roller rotor (Banbury 、Cam 、Delta are optional) |

Rotor material |

4Cr13 |

Rotating speed ratio | 3 :2 | Max temperature | 350℃ |

Max torque | 200Nm | Heating method | Electrical heating |

Temperature sensor | T-type thermo-couples | Heating zone | 3way(4 way temperature measurement) |

Total heating power | 4800W |

| |

Mixer dimension (L*W*H) | 650*500*1450mm | Mixer weight | 92kg |

Packed dimension (L*W*H) | 800*800*1340mm | Packed weight | 112kg |

Ⅴ 、Additional auxiliary equipment project(Optional)

1 、Screw metering feeding and side feeding device

Supply voltage | AC220V |

Power | 120W |

Reduction ratio | 20:1 |

Rotating speed range | 4.5-70r/min |

Main feed volume | 2000ml |

Side feed volume | 1200ml |

2 、Vacuum system(Optional)

Supply voltage | AC380V |

Power | 1.45kW |

Max pumping speed | 0.86m³/min |

Ultimate vacuum | 3300Pa |

Vacuum pump rotating speed | 2880r/min |

Electric current | 3.2A |

Equipment dimension(L*W*H) | 700×650×700(mm) |

3 、Molding traction cutting machine(Optional)

Molding groove width | 80mm |

Thickness range of the molding | 0.3-2mm |

Cooling method of the molding die | Water-cooling |

Traction method | Belt traction |

Traction speed | 0.16-2.45m/min |

Traction electric speed | Manual speed adjustment |

Cutting method | Pneumatic-type |

Cutting width | 120mm |

Total power | 1.0kW |

Voltage | 220V/50Hz |

Weight | 200kg |

Equipment dimension(L*W*H) | 1450x550x1300mm |

5 、Cooling water tank(Optional)

The cooling water tank can directly cool and shape the hose and sheet extruded from the extrusion torque rheometer with a strip die.

Cooling method | Water circulation-type |

Number of rollers | 4 groups |

Number of roller grooves | 5 groups |

Volume of flow | 12000L/h |

Total power | 0. 1KW |

Power supply | AC220V |

Weight | 150kg |

Equipment dimension(L*W*H) | 1250x370x(1000-1200 adjustable)(mm) |

6 、Granulator(Optional)

The machine cuts plastic strips into a granular material for experimental research

Cutter electric motor power | 1. 1kW |

Traction wheel electric motor power | 60W |

Cutting diameter | 90mm |

Cutting size | 0.3-2.35mm |

Cutter rotating speed | 940r/min |

Cutting speed | 5.65m/min |

Weight | 150kg |

Equipment dimension(L*W*H) | 550x470x1050mm |

Ⅵ 、Main configuration

No. | Name | Model | Number | Manufacture |

1 | Measurement and control host | ZJL-200B |

| Changchun Intelligent Instrument Equipment Co.,Ltd. |

Contain | Drive motor and driver | MDME series MFDLNA series | 1 set | Japan Panasonic |

Reducer | KPLF120-15 | 1 | China Hubei Kefeng | |

Torque sensor | Cantilever type | 1 | Changchun Intelligent Instrument Equipment Co.,Ltd. | |

Temperature control module | DTE | 5 | Delta | |

Measurement and control system (Including pressure, temperature, torque, speed, amplifier circuit, etc) |

ZNLB-2015 |

1 set | Changchun Intelligent Instrument Equipment Co.,Ltd. | |

2 | Mixing unit | Standard 60ml |

| Changchun Intelligent Instrument Equipment Co.,Ltd. |

Contain | Heating plate(Including heating element) |

| 3 pics | Changchun Intelligent Instrument Equipment Co.,Ltd. |

Pressing device |

| 1 set | Changchun Intelligent Instrument Equipment Co.,Ltd. | |

Rotor | (Roller-type) | 2 pics | Changchun Intelligent Instrument Equipment Co.,Ltd. | |

Gear box |

| 1 set | Changchun Intelligent Instrument Equipment Co.,Ltd. | |

3 | Extruder unit |

|

|

|

Contain | Twin screw | (L/D: 40:1) | 1set | China Zhejiang |

Screw cylinder |

| 1 | Changchun Intelligent Instrument Equipment Co.,Ltd. | |

Metering feeding device |

| 1 set | Changchun Intelligent Instrument Equipment Co.,Ltd. | |

Heating device | 7 way | 1 set | Changchun Intelligent Instrument Equipment Co.,Ltd. | |

Vacuum connector and negative pressure gauge |

| 1 set | Changchun Intelligent Instrument Equipment Co.,Ltd. | |

4 | Twin screw die | L:D:10:3 |

|

|

5 | Test software |

|

|

|

Contain | Polymer melt measurement data processing software |

| 1 set | Changchun Intelligent Instrument Equipment Co.,Ltd. |

Extruder data processing software |

| 1 set | Changchun Intelligent Instrument Equipment Co.,Ltd. | |

Mixer data processing software |

| 1 set | Changchun Intelligent Instrument Equipment Co.,Ltd. | |

6 | Computer controlled system |

|

|

|

Contain | Brand computer | Standard | 1 set | Domestic brand |

Ⅶ 、Structure principle and performance features

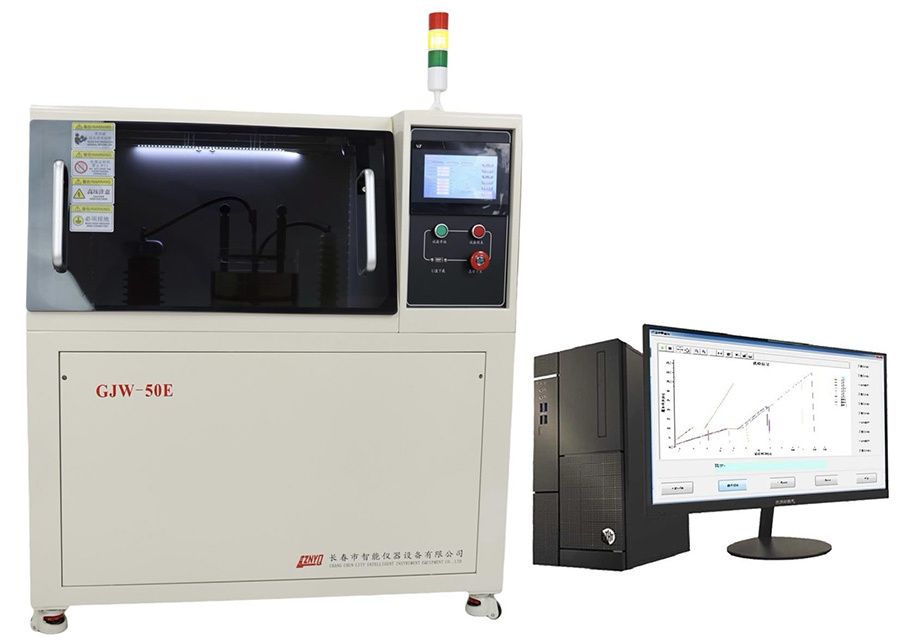

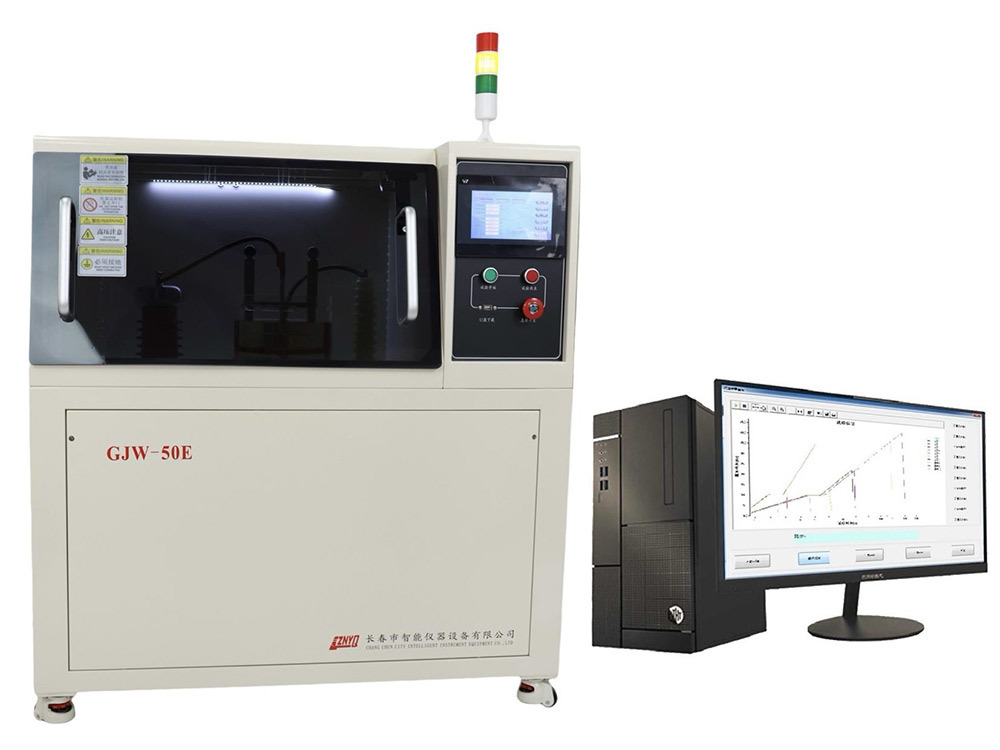

1)Structure and composition:A main measuring and controlling machine is independently connected with the mixer or single-screw extruder or twin-screw extruder under different requirements to form two modes of mixing rheometer and extrusion rheometer, which can be identified by the program.

1 、ZJL series torque rheometer, in addition to the main part of the host machine, extruder, mixer,

computer, can also be equipped with automatic weighing unit, measuring unit, three-roll calendering, screw extruder, film blowing machine, strip sample calendering and traction unit, film quality test unit. More testing can be done with these units.

2 、Automatic weighting unit:It can automatically measure the relationship between the apparent viscosity of the material and the shear rate and shear stress.

2 、Diameter measuring unit:Complete the automatic measurement of die expansion.

3 、Strip sample calendering and traction unit: can produce uniform strip samples for tensile and thermal extension experiments.

4、Film quality test unit:It can complete the test of impurity particle defect and transparency of transparent materials.

The above optional units (conventional configuration does not include the above units) can be

combined with the measurement and control host and computer as the core and other components to form different experimental systems. These functions are in a leading position in China.

Host machine:It is mainly composed of body, drive motor and driver, reducer, torque sensor, temperature control system, measurement and control system, computer data processing system, etc

Temperature and control system:

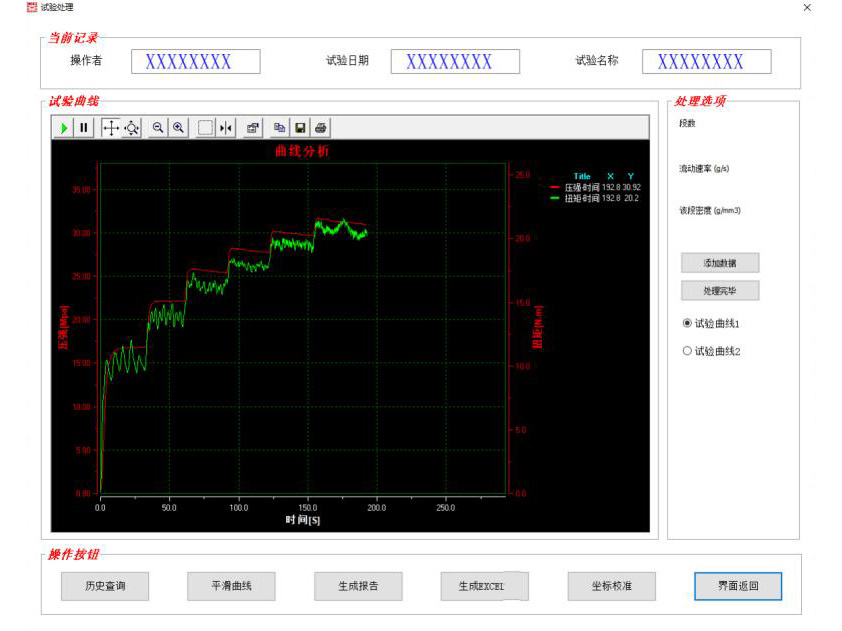

2)System software

The supporting software set consists of Mixer -- mixer test and control software, Plastic -- extruder test and control software, WinNian -- apparent viscosity test data processing software.Mixer and Plastic software interface has rich functions, which can complete the measurement, setting and control of speed, torque, temperature and pressure, and the curve window can display the curve of the above data and the time in real time.

ZJL-200B torque rheometer is an automatic test instrument with computer as the core.Data acquisition, control and test data processing are all completed by the corresponding software, which not only makes the instrument easy to operate, precise control, but also makes test data processing and result output fast and efficient.More importantly, with the support of software, it can complete functions that traditional torque rheometers cannot complete, such as linear acceleration measurement of shear sensitivity of materials. Die correction during measurement of the relationship between apparent viscosity and shear rate of materials.

The design idea of ZJL-200B torque rheometer is to achieve function expansion and performance improvement through software development without increasing the hardware equipment, so it has a high performance-to-price ratio.

Mixer and it’s application

The chamber of the ZJL-200B torque rheometer adopts a three-piece structure, electric heating, 3:2 speed ratio, and the volume after adding the rotor is 60ml. It is made of stainless steel material and has good corrosion resistance ,The mixer can be used to perform many experiments, such as PVC material thermal fusion test, thermosetting material curing cross-linking performance test, thermal stability test, shear sensitivity test, etc. Test curve superposition report.

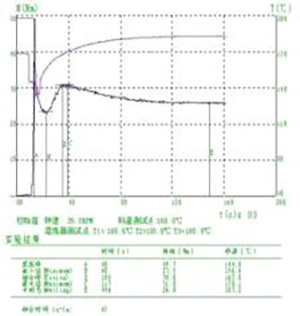

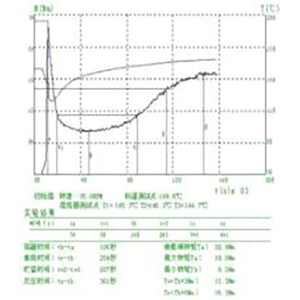

Mixer test curve

Various functional rotors

Mixer test curve

Plastic extruder and apparent viscosity test

The screw length-diameter ratio of the plastic extruder is 40:1 ,the granular and powder screws with different compression ratios can be selected, and the capillary extrusion die, cylindrical extrusion die, tube extrusion die, wire coating die, etc. can be used to perform simulation experiments of different processes. The capillary extrusion die can be used to measure the relationship between the apparent viscosity of the material and the shear rate and shear stress.

Extruder test curve

Keywords

ZJL-200B Building Block (vacuum) Parallel Twin Screw Extrusion platform + mixer Torque Rheometer

Contact Us

Classification