Ⅰ 、Product manufacturing and inspection standards

1 、JB/T7410—94《Specification for the ball indentation hardness testers of plastics》

2 、JJG 369 —1993《Plastics ball indentation hardness testing machine》

Ⅱ 、Applicable test method standards

1 、GB3398.1-2008《Plastics-Determination of hardness-Part 1: Ball indentation method》

2、ISO2039-1:2001《Plastics-Determination of hardness-Part 1: Ball indentation method》

Ⅲ、Scope of application

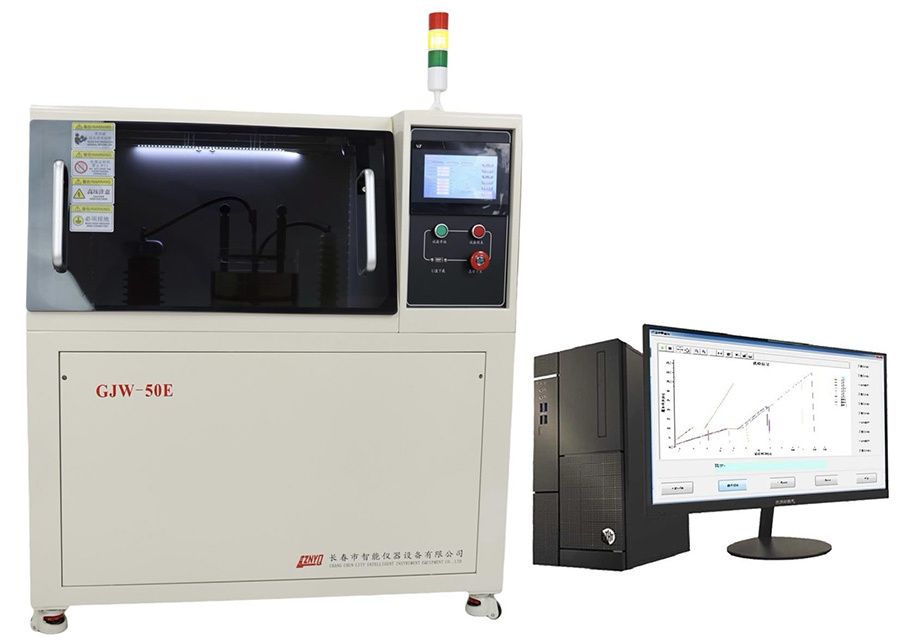

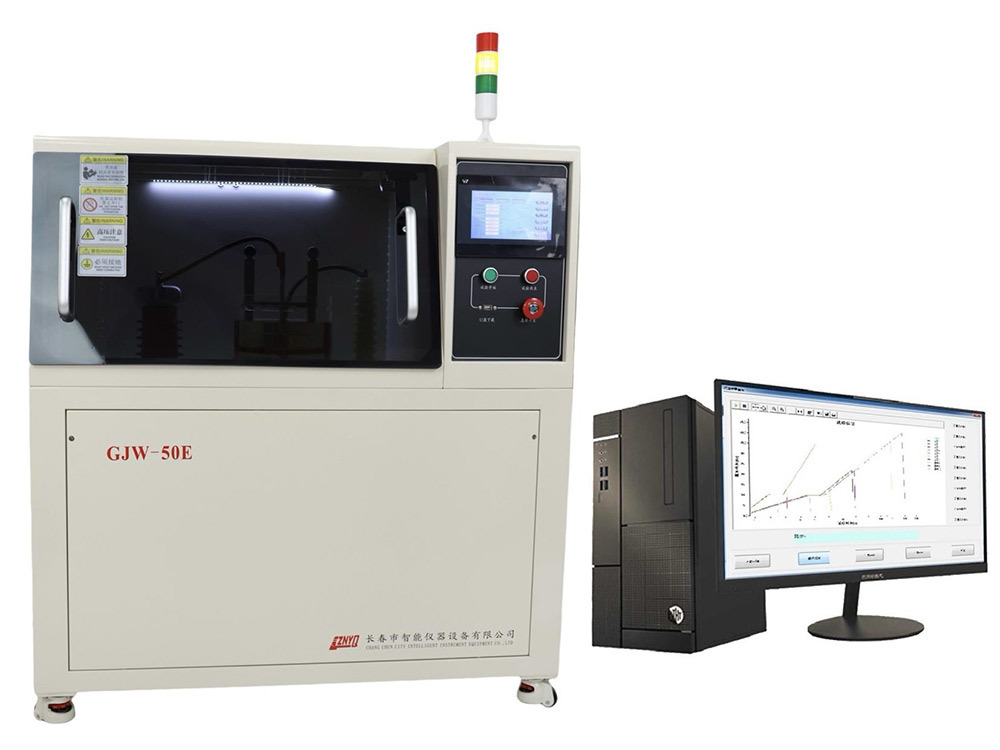

The instrument can be used to test the hardness of materials in automotive engineering plastics, plastic building materials and other industries, and can process and print the data. The machine adopts color touch screen technology, which makes the operation simpler, more intuitive and the

Ⅳ 、Main technical parameter

1 、The test load is divided into five levels:49N 、132N 、358N 、612N 、961N

2 、Preload:9.8N

3 、Steel ball indenter: Φ5mm, Φ 10mm

4 、Minimum scale division for indentation depth indicator:0.001mm

5 、Maximum allowable height of sample:10mm

6 、Distance from pressure head to machine wall:55mm

7 、Distance from pressure head to base: 25mm

8 、Indication accuracy: ±4%

9 、Effective measuring range:0.150~0.350mm

10 、Frame deformation:≤0.05mm

11、Equipment weight:44kg | Packed weight:58kg

12 、Equipment dimension(L*W*H):360*230*460mm | Packed dimension:480*350*720mm

Ⅴ 、Host machine and accessories

Ⅵ 、Structure composition and principle

Name | Specification | Number | Manufacturer |

Host machine (Contain the following) | QYS-96B | 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

High accuracy sensor | LCD10KN | 1 | Changchun |

Deformation sensor | 0-6.5mm | 1 | Domestic |

Pressure head | Φ5mm 、Φ10mm | 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

Base |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

Micro-printer | WH-E22 | 1 | China Beijing Weihuang |

Deformation acquisition system |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

Loading control system |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

Data micro-processing system |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

Single-chip computer software |

| 1 | Changchun Intelligent Instrument Equipment Co., Ltd |

It’s mainly composed of host machine、indenter、loading device、deformation acquisition system

micro-processing system and etc.

Color crystal touch screen

Plastic hardness refers to the ability of a plastic material to resist being pressed into it by another rigid object that is considered to be non-elastic and non-plastic.

The plastic ball indentation hardness test is to use a steel ball of a specified diameter to vertically press into the surface of the sample under the action of the test load, and read the indentation depth value after a certain period of time. The hardness value can be obtained by calculation or table lookup.

1 ﹑ Sample thickness is not less than 4mm, the adjustable range of loading speed is 2 - 7 seconds, usually 4-6seconds, the loading time is 30 seconds or 60 seconds;the load size is selected according to the hardness of the sample, high hardness can choose a larger load, otherwise, choose the smaller load.If the hardness of the sample can not be predicted, it must be gradually upgraded from a small load, so as not to damage the steel ball indenter and the sample;Generally, the test can be carried out as long as the load is selected according to the specified requirements of the sample.

2 ﹑ Ball indentation hardness refers to the average pressure per unit area when a steel ball of specified diameter is vertically pressed into the surface of the specimen under the action of the test load and maintained for a certain period of time, expressed in Kgf/mm2 or N/mm2.

It’s expression is:

H =0.21 p / 0.25πD ( h -0.04)(kg/ mm2)

P―Load (kg)

h―Depth of indentation (mm)

D―Steel ball diameter(mm)

π―Pi

Note:h =h1-h2

h1:The pressed depth of the sample load(mm );

h2:Deformation of the instrument frame under the test load(mm)

Ⅶ 、Sample requirements

1 ﹑ The sample should have uniform thickness, smooth surface, no bubble, no mechanical damage and no impurities.

2 ﹑ Sample thickness should not be less than 4mm, the sample size should ensure that the distance between the center of each measuring point and the edge of the sample is not less than 10mm, the distance between the center of each measuring point is not less than 10mm,the recommended sample size is40×40×4mm or Ф50× 4 mm。

Ⅷ 、Matters needing attention

1 ﹑During the test, it must be ensured that the applied force is perpendicular to the surface of the sample, the supporting surface of the sample must be in good contact with the workbench, and the load should be stable during the test without impact and vibration.

2 ﹑ Install the indenter or replace the workbench should first test several times, so that the hardness tester is in working condition, and then the hardness test can be carried out.

3 ﹑The number of tests in each test is not less than 3 times.

Ⅸ 、Maintenance of hardometer

1 ﹑ The hardness tester must be installed in a dry place with no vibration source, dust or corrosive gas nearby.

2 ﹑ When using a hardness tester, the hardness measurement must be carried out within the specified hardness range. If the hardness range of the sample being tested cannot be determined, the load should be selected and increased step by step from small to large.。

3 ﹑The hardness tester shell should be well connected, and the power supply should be cut off after use.

4 ﹑ The hardness tester should always be kept clean and covered after use to prevent dust intrusion and rust.

Keywords

QYS-96B Plastic ball indentation hardness tester

Contact Us

Classification